The following is an introduction to ABB robot spare parts and the PLC system:

ABB Robot Spare Parts

Teach Pendant: It is a user interface used for programming, controlling, and monitoring the operation of robots. Models such as 3HAC028357 - 001/DSQC - 679 are examples. Through it, the robot can move along the set path. Common accessories include the teach pendant liquid crystal display screen, switch buttons, emergency stop buttons, etc.

Cables and Wires: This includes control cables, power cables, encoder cables, etc. They are used to connect various components of the robot for data transmission and power transmission. They have the characteristics of strong anti-interference performance, wear resistance, bending resistance, high-temperature resistance, low-temperature resistance, and good fire resistance.

Motors: They provide power for the robot. Motors of models such as 3HAC9780 - 1 and 3HAC3579 - 1 are available, and there are different types such as servo motors.

Power Modules: They provide stable power for the robot. Power modules such as 3HAC12928 - 1/DSQC604 and 3HNA023093 - 001 are designed to meet the specific power requirements of ABB robots and have the characteristics of high efficiency, energy conservation, and sturdiness and durability.

I/O Boards: They are used to receive and send various signals to control the actions of the robot. Examples of I/O board models include DSQC651/3HAC025784 - 001 and DSQC652/3HAC025917 - 001.

SMB Board: That is, the serial measurement board. For example, the 3HAC031851 - 001 DSQC633A is used for the measurement and feedback functions of the robot. There is also a related SMB battery, such as the 3HAC16831 - 1 10.8V battery.

ABB PLC System

Hardware Composition

Controller: It is the core part of the PLC, responsible for receiving and processing signals from the input module, executing the logical operations in the program, and sending the results to the output module.

Input Module: It is used to receive external signals, such as sensor signals, and convert external physical signals into digital signals that the PLC can process.

Output Module: It is used to send signals to external devices, such as actuator signals, and convert the control signals of the PLC into physical signals that can drive external devices.

Communication Module: It is used for data exchange with other devices to achieve distributed control and remote monitoring. It supports a variety of communication protocols and can be seamlessly connected to other devices and systems.

Power Supply: It provides the required power for the entire PLC system to ensure the stable operation of the system.

Software Composition

Programming Software: It is used for writing and debugging PLC programs, including program codes for logical control and motion control, etc. It supports multiple programming languages, such as ladder diagrams, instruction lists, function block diagrams, etc.

Configuration Software: It is used to configure the hardware, network, and communication parameters of the PLC system, making it convenient for users to carry out system settings according to actual needs.

Monitoring Software: It is used to monitor and record the running status and performance parameters of the PLC system, so that operators can conduct fault diagnosis and performance optimization. It can display the running situation of the system and alarm information in real time.

Features

High Reliability and Stability: Adopting advanced hardware and software technologies, it can operate normally in harsh industrial environments, process a large number of input/output signals, and ensure the stable and reliable operation of the system.

Flexibility and Scalability: It supports a variety of communication interfaces and protocols, can be seamlessly connected to other devices and systems, and adopts a modular design, which can be expanded and upgraded as needed to adapt to application requirements of different scales and levels of complexity.

Bentley 3500 series module sup

Bentley 3500 series module sup

ABB module supplier Guizhou Yu

ABB module supplier Guizhou Yu

ABB supplier

ABB supplier

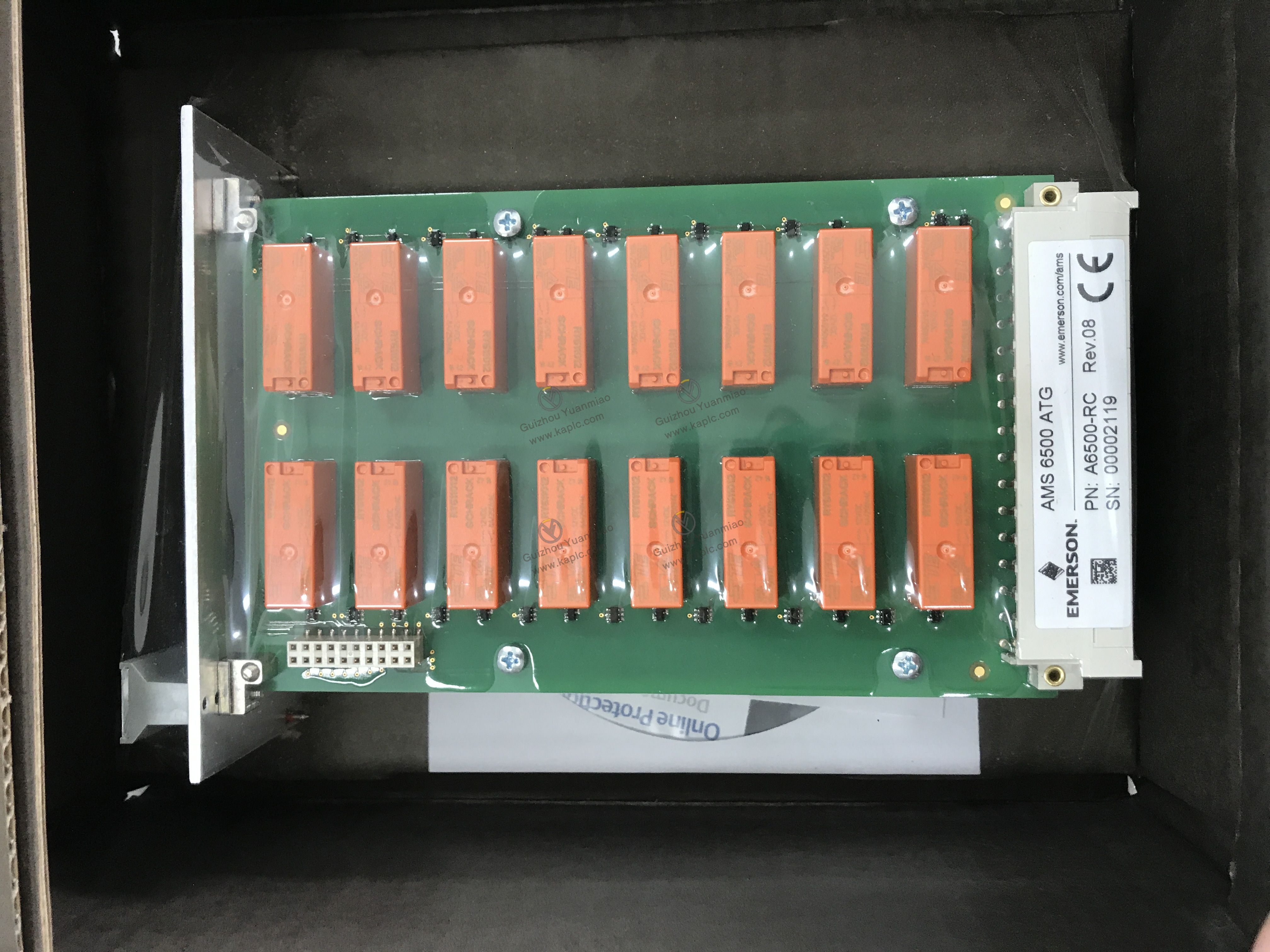

A6500-RC

A6500-RC