The HIMatrix series of safety-related controllers is an advanced PLC platform launched by the German company HIMA, specifically designed for various safety-critical applications. The following is a detailed introduction:

Features and Advantages

- High Safety Level: It complies with the SIL 3 (or higher) safety level standard, and some systems reach the SIL 4 standard. At the same time, it has passed a variety of high-standard certifications such as CENELEC SIL 3 and PL e (Category 4), which can provide a high level of safety performance and is suitable for application scenarios with strict safety requirements.

- Fast Response: Equipped with a high-performance processor, the response time of the background architecture is less than 10 milliseconds. It can quickly process a large amount of input and output data, ensuring rapid response of the system in application scenarios with stringent time requirements.

- Strong Communication Capability: It supports a variety of industrial network protocols, such as Safety Ethernet, Profibus-DP master & slave, OPC, Modbus RTU/TCP master & slave, Send & Receive TCP, Ethernet/IP, Interbus master, etc. It can interact with other safety-related devices through multiple interfaces such as Ethernet, making it convenient for integration with devices from different manufacturers.

- Convenient Programming: The application software ELoP II factory or SILworX engineering tool can be used to achieve convenient module drag-and-drop programming. The mouse drag-and-drop operation is intuitive and simple, enabling faster verification and debugging.

- Modular Design: The modular structure makes the installation and maintenance of the system more convenient. Various control and remote I/O modules have a compact structure and can be flexibly configured and expanded according to actual needs.

- Strong Anti-interference Ability: It has a high anti-interference ability. With multiple redundancies, fail-safe design, and extremely strict testing standards, it ensures stable operation in harsh industrial environments.

Functions

- Implementation of Safety Functions: Various safety functions, such as emergency stop and interlock, are realized through safety logic, which can ensure the safety of the production process and prevent accidents from occurring.

- Monitoring and Control: It can collect analog signals of process variables, such as temperature, pressure, etc., and output control signals to control actuators, such as valves, motors, etc.

Common Models and Configurations

- HIMA F35: It is a high-performance safety-related controller. It integrates multiple functions such as digital input and output, analog input, and counter. It has 24 digital input channels, 8 digital output channels, and 8 analog input channels, and the operating voltage is 24VDC.

- HIMA F3 DIO 16/8 01: It has 16 digital input channels and 8 digital output channels.

- HIMA F3 DIO 20/8 02: It has 20 digital input channels and 8 digital output channels. It is a compact metal shell system with a static error rate of only 1%. It has a wide speed regulation range, a fast dynamic response process, and also has an overload protection function.

Application Areas

- Chemical and Petrochemical Industries: It is used to control and monitor complex chemical production processes, petroleum refining processes, etc., to ensure the safety and stability of the production process.

- Offshore Oil Platforms: As a safety control system, it conducts safety monitoring and protection of various equipment and process flows on the platform.

- Long-distance Pipelines and Oil & Gas Stations: It guarantees the safety of the oil and gas transportation process and realizes the monitoring and control of parameters such as pipeline pressure and flow.

- Metallurgical and Building Materials Industries: In the processes of metal smelting and building materials production, it provides safety protection and control for key equipment and process flows.

- Automobile Manufacturing Industry: It is used for safety control on automobile production lines, such as safety protection for robot operations and automated conveying systems.

- Transportation Industry: For example, in rail transit, it conducts safety control on the signal system, vehicle control system, etc., to ensure the safe operation of transportation.

Bentley 3500 series module sup

Bentley 3500 series module sup

ABB module supplier Guizhou Yu

ABB module supplier Guizhou Yu

ABB supplier

ABB supplier

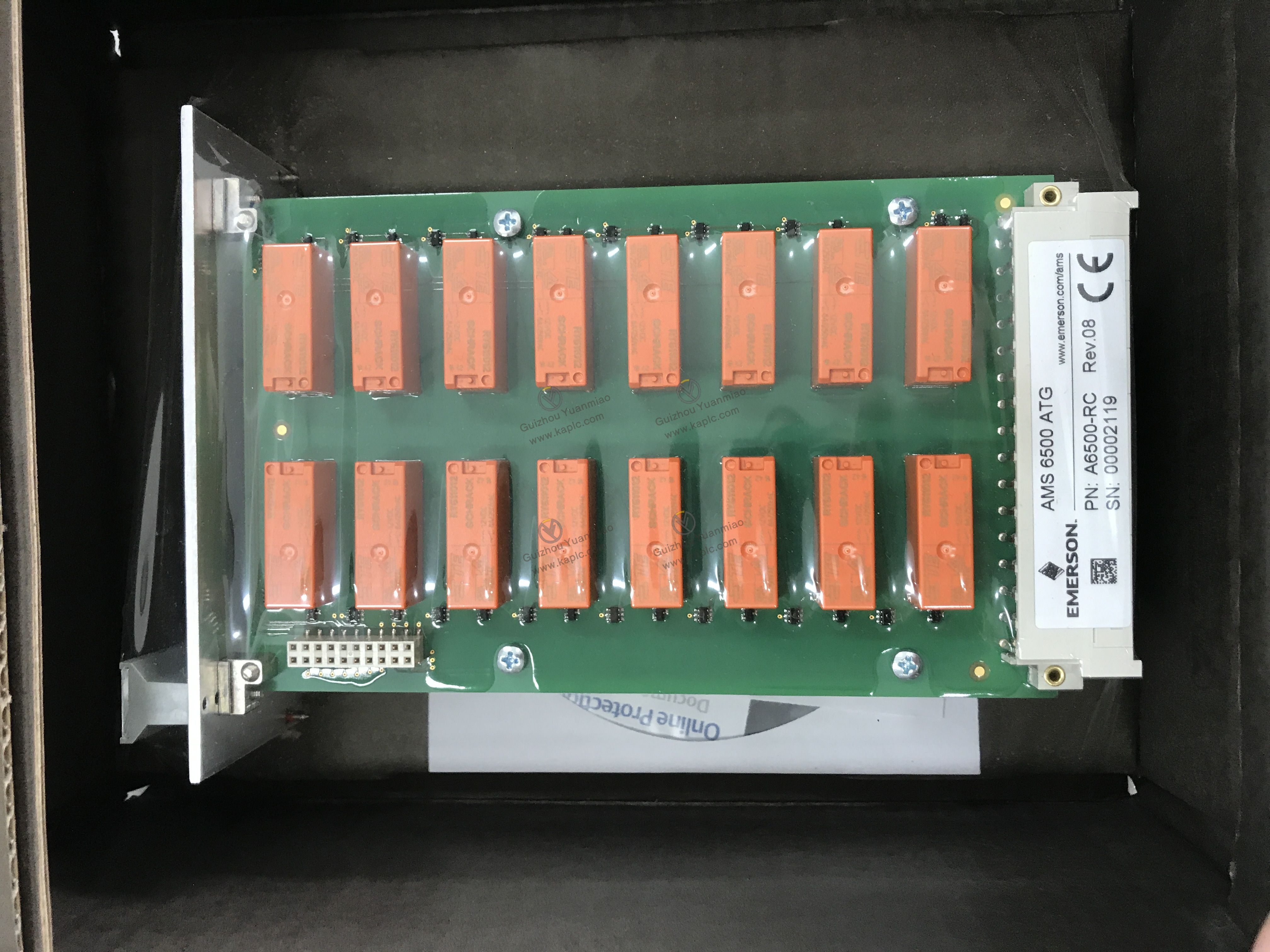

A6500-RC

A6500-RC