Today, let’s delve into the composition of the Bently Nevada 3500 rack protocol series. The 3500 series, leading mechanical protection and condition monitoring system, comprises three core components: the rack, modules (e.g., vibration monitoring, speed control, communication modules), and software. The rack serves as the hardware foundation, supporting hot-swappable modules to ensure system reliability and maintainability.

- Structure: Available in two sizes:

- Full-size 19-inch rack: Supports 14 module slots for large-scale applications (e.g., steam turbines, compressors).

- Compact 12-inch rack: Features 7 slots for smaller systems (e.g., pumps, fans).

- Key Features:

- Hot-swappable design: Allows module replacement without powering down the system, minimizing downtime.

- Redundancy support: Compatible with dual-power modules (e.g., 3500/15) and redundant communication paths for high availability.

- Environmental resilience: IP54 protection and G3 anti-corrosion coating for harsh industrial environments (e.g., petrochemical plants, power stations).

The system supports modular expansion with specialized functions:

- Vibration Monitoring Modules:

- 3500/40M/42M: 4-channel eddy current sensor inputs for radial vibration, axial displacement, and shaft eccentricity. Features REBAM® (Relative 轴振动报警监测) and 4-20mA analog outputs.

- 3500/44M: SIL 2-certified for safety-critical applications, supporting dual-channel vibration and displacement monitoring.

- Speed/Torque Modules:

- 3500/53: Overspeed protection with peak speed locking, ideal for high-speed rotating machinery.

- 3500/50: High-precision speed measurement for control systems (e.g., gearboxes, generators).

- Temperature Modules:

- 3500/60/65: Supports RTDs (e.g., Pt100) and thermocouples, with 6 or 16 channels for bearing/pipeline temperature monitoring.

- Communication Modules:

- 3500/92: Ethernet/serial gateway supporting Modbus TCP/RTU and proprietary Bently Nevada protocols, enabling integration with DCS (e.g., ABB System 800xA, Siemens PCS 7) and SCADA.

- 3500/22M: Transient Data Interface (TDI) for real-time vibration waveform acquisition by System 1 software.

- Relay/Safety Modules:

- 3500/34: Triple Modular Redundancy (TMR) relay module for fail-safe shutdowns, compliant with API 670 and IEC 61508 standards.

- Configuration Tools:

- 3500 Rack Configuration: Graphical software for module parameter setup, alarm configuration, and diagnostics (Windows-compatible).

- Monitoring & Analysis:

- System 1: Advanced analytics software for vibration spectrum analysis, trend prediction, and fault diagnosis (e.g., unbalance, misalignment).

- Integration:

- Supports OPC UA, MQTT, and Modbus for data sharing with enterprise-level systems (MES, IIoT platforms).

The "rack protocol" refers to internal and external communication mechanisms:

- Backplane Bus: Proprietary high-speed bus for data exchange between modules (e.g., vibration data from 3500/42M to 3500/92 gateway).

- Redundancy: Dual backplane buses in full-size racks ensure fault tolerance during module communication.

- Standard Protocols:

- Modbus TCP/RTU: Widely used for integration with PLCs and DCS, with configurable register mappings (e.g., vibration values mapped to Modbus addresses 40001–40004).

- HART: Supported by temperature/vibration modules for smart sensor communication.

- Proprietary Protocols:

- Bently Nevada Protocol: Used for deep configuration (e.g., firmware updates, advanced diagnostics) via System 1 software or 3500 Rack Configuration.

- Industrial Ethernet:

- 10/100Mbps Ethernet (RJ45) in 3500/92 for OPC UA communication, enabling secure data transfer with encryption (compliant with ISA 99/62443 standards).

- Sensor Data Acquisition: Eddy current/accelerometer signals are converted to digital data by monitoring modules.

- Protocol Conversion: 3500/92 gateway translates data into Modbus/OPC UA for DCS/PLCs or proprietary formats for System 1.

- Control & Alarms: Trigger shutdowns/alarms via TMR relay modules (3500/34) based on DCS commands or internal logic.

- Petrochemical: Monitoring compressors, pumps, and turbines in refineries (e.g., axial displacement protection for centrifugal compressors).

- Power Generation: Steam turbine vibration analysis and overspeed protection in thermal/nuclear plants.

- Metallurgy: Roll mill speed control and bearing temperature monitoring in steel production.

- Input Types: Eddy current (vibration/displacement), accelerometer (shock), RTD/thermocouple (temperature), proximity probes (speed).

- Accuracy: Vibration measurement accuracy ±0.5% of full scale; speed resolution up to 0.01 RPM.

- Sampling Rate: Up to 20 kHz for transient vibration waveform acquisition (3500/22M TDI).

- Redundancy: Dual power supplies (100–240V AC/24V DC), network/controller redundancy for mission-critical systems.

- Hot-Swap Modules: Replace faulty modules (e.g., 3500/40M) in <60 seconds without system interruption.

- Self-Diagnostics:

- Front-panel LED indicators for module health (power, communication, alarm status).

- Software-based diagnostics in 3500 Rack Configuration, highlighting faulty channels or loose connections.

- Predictive Maintenance: System 1 software analyzes vibration trends to predict bearing failure (e.g., detecting outer race defects 3–6 months in advance).

- Standards: API 670 (Machinery Protection), SIL 2 (Safety), IEC 61131-3 (Software), and ISA 95 (Enterprise Integration).

- Documentation:

- Official manuals: 3500 System User Guide, Modbus Communication Specification, available on Bently Nevada Website.

- Configuration tools: Download 3500 Rack Configuration software via GE Digital support portal.

- Caveats: Protocol details (e.g., Modbus register maps, proprietary data formats) vary by module version; always consult the latest technical bulletins for exact specifications.

By combining modular hardware, flexible protocols, and advanced software, the 3500 series sets the standard for rotating machinery protection, ensuring safety, reliability, and predictive maintenance across industrial sectors. For precise protocol configurations or custom integrations, refer to factory documentation or contact GE Digital’s technical support.

Bentley 3500 series module sup

Bentley 3500 series module sup

ABB module supplier Guizhou Yu

ABB module supplier Guizhou Yu

ABB supplier

ABB supplier

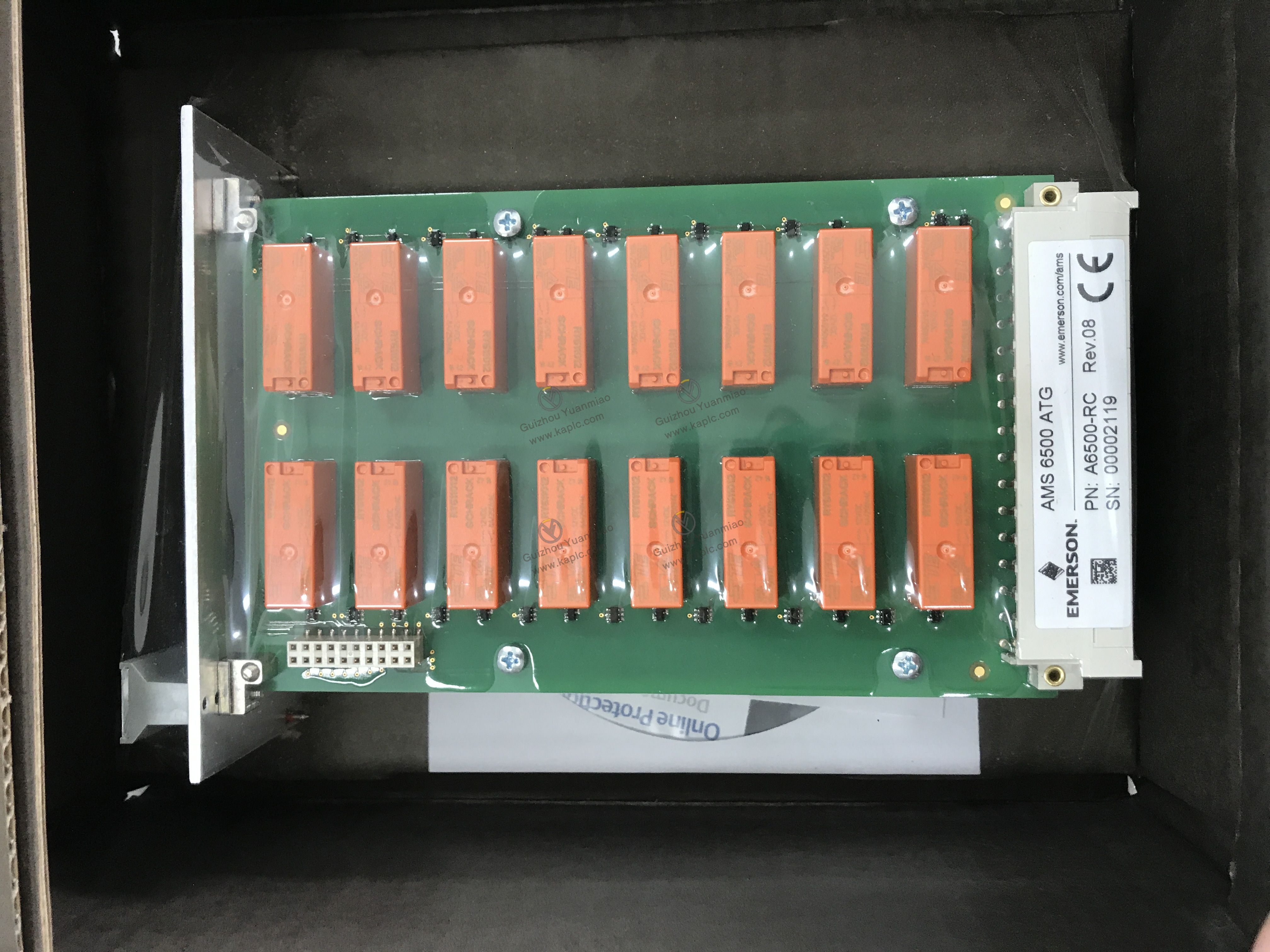

A6500-RC

A6500-RC