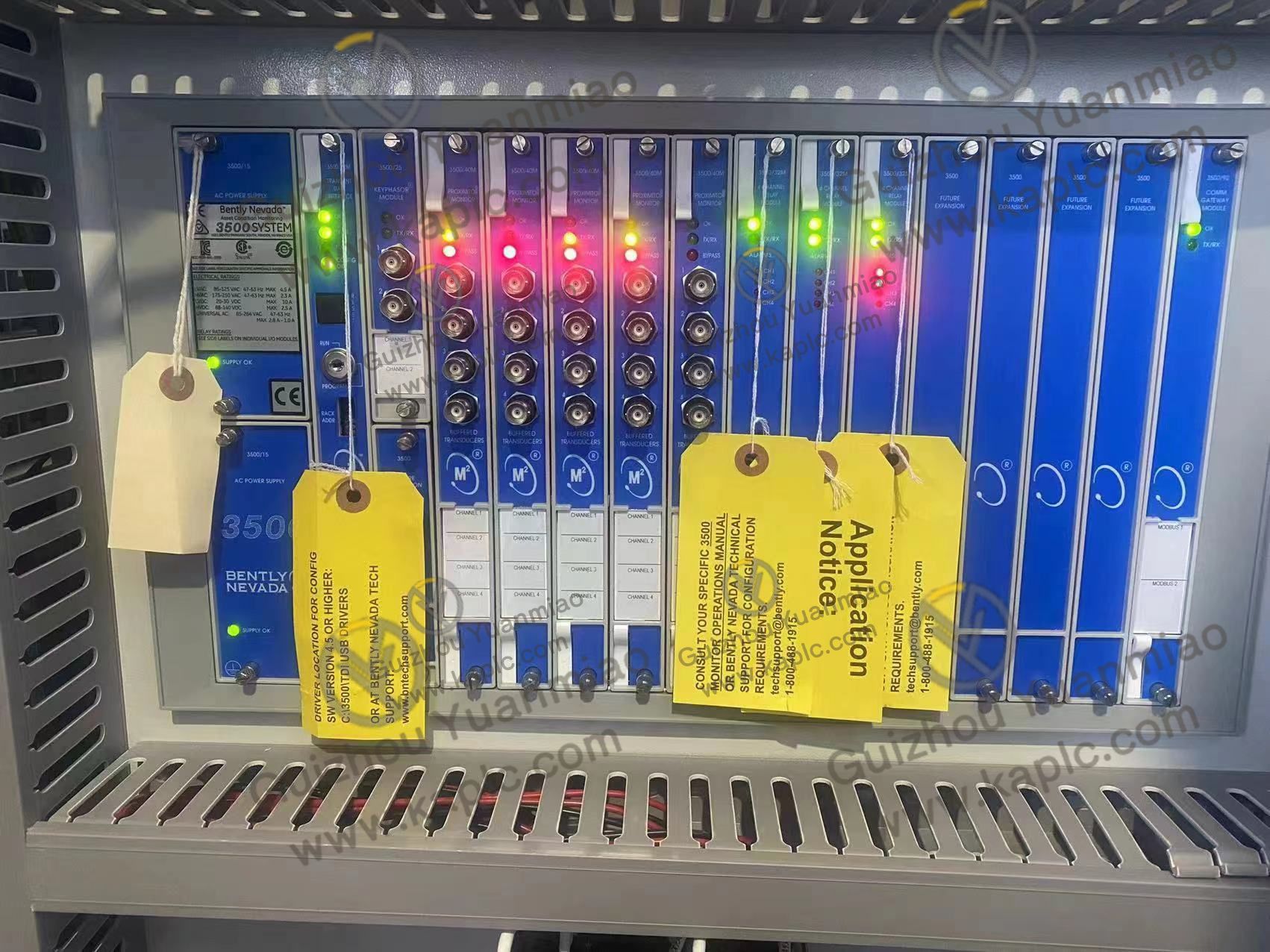

Bentley 3500 series module supplier Guizhou Yuanmiao

The Bentley 3500 series is an online monitoring and protection system launched by GE Bentley Nevada, widely used in the condition monitoring and protection of large rotating equipment. Here is a detailed introduction:

The Bentley 3500 series is an online monitoring and protection system launched by GE Bentley Nevada, widely used in the condition monitoring and protection of large rotating equipment. Here is a detailed introduction:

Scope of application: Suitable for TSI system of large thermal power turbine units, monitoring system of water turbine units, as well as monitoring, protection and analysis of large rotating equipment such as main compressors in the petrochemical industry, blast furnace fans, sintering main exhaust fans, TRT in the steel industry.

Product Features:

Equipped with self detection and fault-tolerant design, it can be configured with multiple redundancy methods, ranging from adding a second fully redundant power supply to a complete triple modular redundancy (TMR) configuration, which can be used for selected channels or all channels to meet critical task applications.

It can seamlessly connect with the Bentley System1 status monitoring and diagnostic analysis software platform.

Communication with factory control and automation systems can be achieved through the communication gateway module.

The design complies with the American Petroleum Institute standard API 670 and the reciprocating compressor application API 618 standard, and has been certified by DNV and Class NK certificates in the offshore application field, as well as certifications from the Canadian Standards Association (CSA), Factory Mutual Assistance (FM), GOST, ATEX, and CE.

System composition and functions:

3500/01 Framework Interface Module: Used to connect sensors and monitoring systems, it is the interface for the system to interact with external devices.

3500/15 power module: provides power support for the system to ensure stable operation.

3500/22M Transient Data Interface Card: Used for communication with System 1 mechanical management software to achieve data transmission and analysis.

3500/40M Displacement Monitor: A configurable 4-channel monitor module used for radial vibration, axial displacement, eccentricity, REBAM, and differential expansion measurements.

3500/42M Vibration Axial Displacement Card: In addition to all the functions of 3500/40M, it can also receive input types of speed, acceleration, and dual probes (speed and displacement) and their related signal adjustments, such as filtering and integration.

3500/53 overspeed detection module: used for mechanical overspeed protection. When the equipment speed exceeds the set value, it will promptly issue an alarm and take protective measures.

3500/62 TSI Turbine Monitoring Module: specifically designed for vibration monitoring of steam turbines, designed and optimized for their operational characteristics.

3500/64M system accessory module: used for system expansion and configuration, can add system functions and modules according to actual needs.

Bently Nevada

3500/15

3500/22M

3500/25

3500/33

3500/42M

3500/45

3500/50

3500/53

In general, the Bentley 3500 series can obtain real-time equipment operation status information through continuous online monitoring, timely discover potential faults and hidden dangers, provide strong guarantees for the safe and stable operation of equipment, and help users reduce maintenance costs and improve production efficiency.

Bentley 3500 series module sup

Bentley 3500 series module sup

ABB module supplier Guizhou Yu

ABB module supplier Guizhou Yu

ABB supplier

ABB supplier

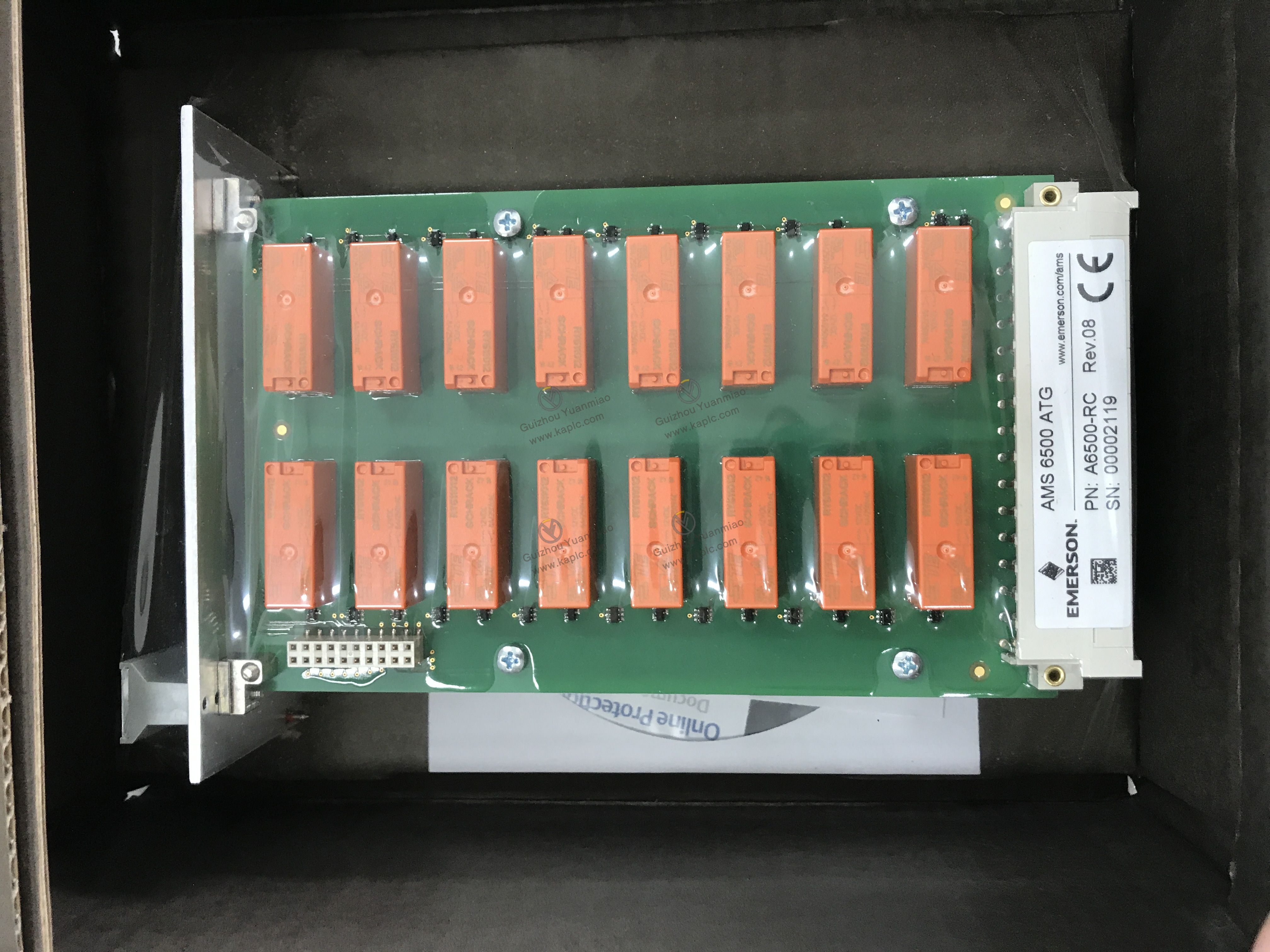

A6500-RC

A6500-RC