The ABB high-voltage variable frequency drive rack of the S-073N series with the product number 3BHB009884R0021 is used for configuring IGCT (Integrated Gate-Commutated Thyristor) thyristors.

Product ID: S-073N

ABB Type Designation: 3BHB009884R0021

IGCTs have become ubiquitous in high-power electronic products and are now available with rated voltages ranging from 4.5 kV to 6.5 kV, and there are three main types: asymmetric, reverse-conducting (RC-IGCT), and symmetric or reverse-blocking (RB-IGCT). Asymmetric IGCTs cannot block reverse voltages above a few tens of volts. Therefore, they are used in places where such voltages will never occur, for example, in switched-mode power supplies, or are equipped with appropriate anti-title pictures. The invention of the IGCT has changed the rules in the field of power electronics. The picture shows an ABB IGCT with a gate device. Over the years, the sealed squeeze package design of the IGCT has proven its reliability in the field. The IGCT chip in the 1c sealed package, together with its integrated gate unit and parallel diode, can conduct current in the reverse direction. For a given chip size, the asymmetric IGCT has a high power level. The RC-IGCT integrates a diode in the same GCT chip to conduct current in the reverse direction, but it uses the chip area that could originally be used for the switching function. The symmetric IGCT can essentially block reverse voltages but can only conduct current in the positive direction. Over the years, the sealed compression package design of the IGCT has proven its reliability in terms of the protection of power semiconductor devices and the load cycling capability. Composed of several carefully designed layers of materials, it will not have problems such as solder voids or bond delamination as experienced by other technologies. It can be an option, and the HPT-IGCT can be improved to adapt to this situation. Therefore, the corrugated p-base doping profile is further optimized to allow for a full SOA (Safe Operating Area) range throughout the temperature up to 140°C. In addition, internal interfaces, such as the wafer, have been improved to achieve a higher thermomechanical performance. The verification of these improvements has begun, and the results look promising. Moreover, this so-called HPT+ technology has a significantly improved technical curve compared to the HPT-IGCT due to its optimized corrugated p-base design.

Reduction of conduction losses: Towards a 1 V conduction state, 3.3 kV IGCTs

In recent years, there has been a trend in many power electronics applications to use multi-level topologies. The operation of such products is usually at a relatively low switching frequency, but there is a need for high current-carrying capacity and/or a high rate at times. Due to the inherently low conduction losses of thyristors.

Integration: High-voltage ratings (10 kV IGCTs) can be manufactured without series connection. For a three-level inverter with a line voltage of 6 to 6.9 kV, if an IGCT with a rated voltage of 8.5 to 10 kV is available. Such a device provides a simple mechanical design, has a lower control complexity, and a higher reliability compared to the series connection of two 4.5 or 5.5 kV devices for a line voltage of 6 to 6.9 kV. To prove the feasibility of this approach, the HPT platform and concept are used.

Improved thermal performance:

High-temperature IGCT

One way to increase the output power of existing converter designs is to increase the use of power semiconductor devices. However, for continuous operation, the capacity of the cooling system may limit this growth. However, for intermittent high-power operation, the temperature rise

Integration: RB-IGCT

Bentley 3500 series module sup

Bentley 3500 series module sup

ABB module supplier Guizhou Yu

ABB module supplier Guizhou Yu

ABB supplier

ABB supplier

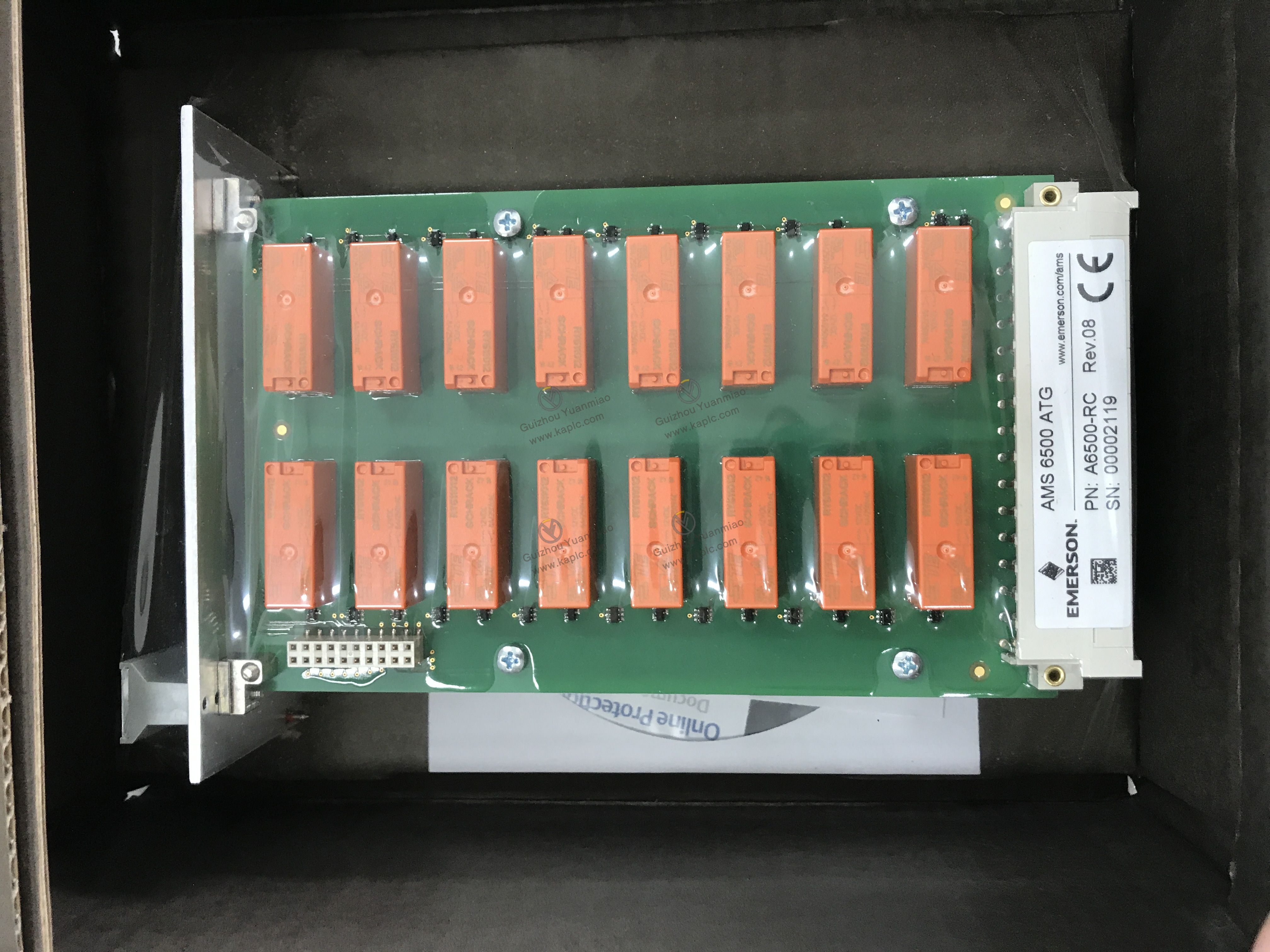

A6500-RC

A6500-RC